Marking

Take advantage of these valuable marking tips and tricks. Learn how to ensure clear marks.

Marking vol.1

What type of laser is suitable for marking on metal materials?

KEYENCE offers several types oflaser markers:

- UV (355 nm wavelength)

- Hybrid (1064 nm wavelength)

- Fiber (1090 nm wavelength)

- CO2(10600 nm wavelength)

- Green (532 nm wavelength)

CO2laser markers cannot mark on metals. Hybrid or Fiber laser markers are better suited for most metal marking applications.

Is it possible to read characters marked on a transparent PET bottle?

Yes,laser markingcan absolutely mark transparent bottles. In fact, CO2laser markers are commonly used on bottling lines to print lot codes and expiration dates.

KEYENCE offers a short wavelength CO2laser marker that's optimized for PET marking. This system enables enhanced coloring and minimal damage to the surface of PET bottles.

With the ML-Z Series:

Three-dimensional objects can be printed easily and freely.

清晰的印刷是自己e even on a high-speed line.

Is it possible to print on and make perforations in transparent film?

Yes, but you need to choose the right system. Most laser markers will cause small pinholes to appear inside printed characters due to the heat of the beam. Short wavelength lasers overcome this common problem, and can both mark and cut films with a high degree of accuracy.

9.3 μm short wavelength laser

For resin products such as PET, PC, etc.

KEYENCE's ML-Z series laser markers come in two distinct wavelengths: 10.6 μm and 9.3 μm. The short wavelength models have been specially optimized for the heat absorption characteristics of resins.

As a result, the 9.3 μm laser markers are able to print shallow engravings with high visibility and less surface swelling than their counterparts. This guarantees outstanding, high quality markings on films and sheets that would be otherwise impossible.

What is the depth of my mark?

A mark's depth depends on the laser marker type, the parameters used to create the mark and the target material.

For example, the depth of a single mark on plastic can be easily controlled and varied (from a few microns to over 1mm). However, metal marks are typically only 10-90 μm deep, so deep engraving takes much longer to accomplish.

Thus, a wide variety of marking styles are available by simply changing the laser power and marking speed.

What are the biggest and smallest characters I can mark?

The minimum and maximum character sizes depend entirely on a laser marker's model and type. KEYENCE laser markers can create clear characters that range in size from 0.1 mm (0.004") to 300 mm (11.81").

Is it possible to mark on ceramics?

Yes, it is possible to laser marker ceramics. However, different laser markers are better at marking different ceramic types.

For example, KEYENCE's CO2laser markers are ideal for marking alumina ceramics, whereas hybrid laser markers are better at marking zirconia ceramics. It is recommended to test different marker types to find the best results.

Marking vol.2

What happens when my target moves out of focus?

Laser markers typically produce their best marks when a target is at their beam's focal point. The further the target gets from the focal point, the less focused the laser spot becomes. Eventually, markings become faint due to the enlarged beamspot and decreased energy density.

Below are some examples of what marks look like when a target moves out of focus.

Marking on steps

Marking on a slope

Marking on a cylinder

Marking on a cone

KEYENCE's range of 3-Axis Laser Markers solves all of the problems above.

Laser displacement sensors enable in-focus marking on targets that move further from or closer to the laser marker.

- Automatic Focusing

- KEYENCE laser markers can adjust their focus in real-time. As a result, changes in target sizes can easily be accounted for without the need to continuously reset the system.

Is it possible to mark my company's logo?

Yes, it's possible to mark various logo and graphic data by using KEYENCE's Marking Builder software. DXF files can be easily loaded to the laser marker as a logo file, making it possible to quickly mark company logos as desired. Additional control over logos is also possible with Marking Builder, such as selecting the hatching style or the laser marking path.

Easy-to-use editing tool, Logo Designer

- 1. List display

- An element's information, including start/finish coordinates and marking order, are displayed and can be easily changed.

- 2. Disconnected line detection

- The software displays the parts of a frame line that are not connected, making it possible to easily modify broken outlines before hatching.

- 3. Various hatching styles

- Easily edit and hatch elements without the need for specialized CAD software. Ideal hatching patterns can be selected based on the desired outcome, from diagonal lines to crossed and contoured lines.

Are 2D codes readable when marked on metal targets?

Yes, laser markers can create highly readable 2D codes on metal targets.

Black 2D codes are easily read on most metal surfaces (such as iron and stainless steel). However, black 2D codes on matte surfaces cannot be easily read. To overcome this problem, readable 2D codes can be marked by first creating a "polished" white background with the laser and then marking the black 2D code on top.

How difficult is it to mark ●, ▲, and ■ characters?

Simple shapes, such as circles, triangles and squares, can be easily created in KEYENCE's Marking Builder software. The built-in logo designers enables quick, easy creation and manipulation of user-defined custom characters and fonts.

Logo/Custom Character Editor

Is it possible to count or change values when marking serial numbers?

是的,日本基恩士激光标记可以计数和改变lues when marking serial numbers. This can be done using an internal counter or via serial communication.

Internal counters can respond to various cases since it is possible to change the number of steps, repetitions and base counter value. It's also possible to reset a counter or count directly from the laser marker's discrete I/O terminal.

Serial communication allows for configured counters or marking blocks to be changed directly as desired.

Counter settings

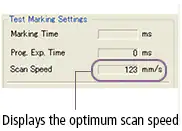

How can I ensure that a target will be marked within a given time frame?

允许用户扫描速度优化的方法to automatically calculate the correct scan speed settings to complete marking within a given time frame. This function can be used to calculate scan speeds when marking moving targets as well.

- 1. Put a check mark in the "Optimize" box

- 2. Set the desired marking time

- 3. Then simply click “Scan Optimize”

Marking vol.3

How can I mark characters to represent the time shift in which a part was marked?

Time shifts can be easily customized and marked through KEYENCE's Marking Builder software.

A maximum of 24 shifts per day can be replaced with characters.

This enables printing by updating the alphanumeric characters automatically according to a laser's internal clock.

The following is an example of dividing a day into three shifts and replacing them with alphabetical characters.

How can the marking time be decreased?

In some cases, it is possible to simply increase a laser's scan speed in order to decrease the marking time. However, this can lead to poor marking quality. In these instances, changing the fill direction can be an effective way to decrease marking time.

Example of changing the direction of the fill

It is possible to change the direction of marking inside of a pattern as well as the order in which the patterns are marked to increase efficiency and decrease marking time.

Does changing the Q-Switch frequency of a fiber or YVO4laser effect marking quality?

KEYENCE's hybrid (YVO4) laser markers have a Q-Switch range of 0-400 kHz. Generally speaking, a lower Q-Switch value allows the laser to build up more power before being released onto a part. This is beneficial when deep marking or slower marking speeds are required. High Q-Switch values mean that the laser is pulsing more frequently and not delivering as much power per pulse. This is useful when damage-free marking or high speeds are required.

The examples below illustrate why marking with a higher Q-Switch value is necessary for high-speed applications.

What is the Q switch?

An optical component that generates high energy through controlling laser oscillation.

Can marking be accomplished on plated surfaces without removing the surface layer?

It is impossible to laser mark a part without causing some effect to the target's surface. However, it is possible to limit the amount of part damage by finely adjusting the marking parameters. The example below shows a mark on galvanized metal where the marking depth has been controlled to within 1 μm (0.04 Mil).

Difficult to mark materials (such as gold, due to its high reflection ratio) can still be clearly and quickly laser marked as long as the right wavelength is used.

How can I quickly find the right marking parameters for my part?

KEYENCE laser markers come equipped with a “Sample Marking" function that greatly simplifies the process of finding the right marking parameters.

Sample marking allows users to quickly test different power, scan speed, Q-Switch frequency and focal distance combinations at the same time.

This drastically reduces the time and scrap required to dial in a mark.

Sample marking example

| Scanbeat (mm/s) | |||||||

|---|---|---|---|---|---|---|---|

| 500 | 1000 | 1500 | 2000 | 2500 | 3000 | ||

| Laser power (%) | 20 | A0 | A5 | AA | AF | AK | AP |

| 25 | A1 | A6 | AB | AG | AL | AQ | |

| 30 | A2 | A7 | AC | AH | AM | AR | |

| 35 | A3 | A8 | AD | AI | AN | AS | |

| 40 | A4 | A9 | AE | AJ | AO | AT | |

Up to 123 combinations can be at once. Alphanumeric labels help operators select the correct pattern and also represent how single line characters will appear when marked. The boxes next to the alphanumeric labels represent how filled patterns and thick text will appear when marked.

Is it better to mark slowly when etching metal targets?

Generally speaking, slower scan speeds tend to create deeper, more legible marks. However, too slow of a scan speed can result in soot deposits that raise a material's surface. Using thick text lines and multiple repetitions usually results in the best etch.

Marking vol.4

Is it possible to print mirrored text?

KEYENCE's Marking Builder software is equipped with a "Mirror Image" function. To enable this, simply check the option box.

MIRROR IMAGE

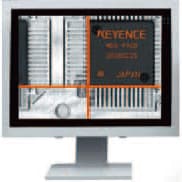

Is there a way to easily position extremely small targets to be laser marked?

Several KEYENCE laser markers contain a built-in camera that can display the marking area on a monitor. This finder function lets users quickly and accurately position parts, even on extremely small targets. Less scrap is produced and initial programming is simplified.

Will marking e-coated products lead to the formation of rust?

为了E-coatings通常应用于部分prevent rust. Removing an E-coat risks exposing the protected product. However, many e-coated products marked with CO2and UV lasers have successfully passed salt spray tests. Before adopting such a system, it is vital to conduct test marking and/or salt spray testing in order to evaluate whether or not laser marking will meet your needs.

Is it possible to mark products that are coated with oil?

Thin coatings of oil are not a problem, but large amounts of oil can block the laser beam. Markings may become distorted, stretched or defective, so products with a thick coating of oil need to be pre-processed with compressed air or wiped down.

Does marking on glass cause cracks?

Glass is transparent, so typical laser light passes straight through and won't leave a mark. CO2laser markers work on glass, but they must apply heat to produce a mark. As a result, it's possible to produce clear, crack-free marking on heat resistant glass (like quartz glass), but soda-lime glass will crack.

It is necessary to mark sensitive glass with repeated scans and low power settings to avoid cracking.

QUARTZ GLASS

EXAMPLE MARKING

Marker used: CO2laser marker

SODA-LIME GLASS

EXAMPLE MARKING

Marker used: CO2laser marker

Can a laser marker be used to create labels?

Yes. In fact, CO2laser markers are commonly used to create many different labels by removing layers of ink from parts.

Unlike conventional printing methods, laser markers aren't limited to inline serial number management. Lasers have a great degree of content flexibility (including logos and 2D codes) and leave behind permanent marks.

Due to the many advantages that laser markers offer, paper labels are quickly being replaced by "laser labels." These labels are specifically designed to react with laser light and produce clear, extremely durable results on demand.

Marking GS1 DataBar barcodes? Now mandatory in the medical industry.

Laser markers can be used with labelers to provide inline marking of best by dates, lot numbers and other variable information.

Creating a nameplate with a laser label

Laser label designs can be easily managed via computer, enabling quick product and information changeovers. This significantly reduces lead time and the man-hours required for inventory management.

CO2lasers can cut away labels from their backing, which lets users easily design a label of their choice.

Marking vol.5

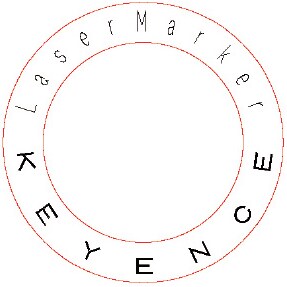

Is it possible to mark characters in a circular layout?

Yes. KEYENCE's Marking Builder software makes it easy to program circular text. Simply set a predetermined radius or click and drag from the center of a text block until it conforms to the part.

In addition, you can create the layout by specifying the center coordinates and arc radius

What is a laser marker's focal point?

A laser marker's focal point is the location in the beam with the highest energy density. When a laser beam becomes unfocused, it can cause variations in marking quality and skewed characters.

Typical laser markers have a fixed focal point. Part changes require physical adjustments, and it's not possible to mark on 3D shapes.

KEYENCE laser markers use 3-axis technology to adjust their focal point by +-21mm anywhere in the marking field without the need for physical adjustments. This allows KEYENCE lasers to mark on 3D shapes, compensate for height differences and purposely de-focus the beam to provide aesthetically pleasing marks.

How can I obtain CAD data of laser marker dimensions?

You can download CAD data from the KEYENCE web site.

For 2D-CAD, DXF files are available.

For 3D-CAD, three types of data files (IGES/Parasolid/STEP) are available.

What benefit does a 9.3 μm wavelength CO2laser marker provide?

9.3 μm laser light has a higher absorption rate in resins, plastics and films, allowing transparent materials to be marked or cut with less heat (and therefore less damage) on the surface of the target.

Because marks generated with a 9.3 μm wavelength laser are shallower, it's much easier to create legible marks. This is due to more light being reflected and less light being trapped within the depth of the mark.

| Standard Type | |||

|---|---|---|---|

| Model | Head | ML-Z9510 | ML-Z9510T |

| Controller | ML-Z9500 | ||

| Marking method | XYZ 3-axis simultaneous scanning | ||

| Marking laser | Wavelength | 10.6μm | 9.3μm |

| Average output | 30W | 20W | |

- Marking effect on transparent materials

-

Conventional laser

Damage to the surface causes a rough mark ML-Z with a 9.3 μm wavelength

Damage is minimized

Can I use a laser marker for small volume production?

Laser markers can be used for large- and small-scale productions. Initial setup and alignment is required for both. However, there are a variety of alignment guide lasers (and cameras in some systems) designed to ensure that the parts will be marked correctly. KEYENCE laser markers can be quickly setup for batch marking and have the ability to mark on moving targets.

The versatile guide laser function can simplify visual laser positioning

(Indicating characters to be marked)

(Indicating character marking range)